22.7.1 Potential-to-Emit, Permit-Limited Potential-To-Emit and Actual Emissions

Applicable air quality regulations use various operating timeframes and conditions to group facilities into air emissions categories. The three categories, which are critical concepts in air permitting, are potential-to-emit, permit-limited potential-to-emit, and actual emissions.

22.7.1.1 Potential-To-Emit

The potential-to-emit emissions (i.e., sometimes simply referred to as the potential emissions) are the emissions that would occur if an operation ran at full capacity 24 hours a day and 7 days a week. The potential-to-emit takes physical and operational limitations into account, but not air pollutant control devices or limitations in the hours of operations[1].

22.7.1.2 Permit-Limited Potential-To-Emit

The permit-limited potential-to-emit is the same theoretical quantity of emissions as the potential-to-emit, except the permit-limited potential-to-emit considers federally enforceable operational limits (e.g., material use limits, hours of operation limits) established by the air permit and the use of control devices. You can request a facility-wide throughput permit limit.

22.7.1.3 Actual

Actual emissions are typically derived using actual operating hours and/or actual material usage, but you have several options for how to do this calculation. For some calculations, you can use the average actual material usage based using several years of data. The actual emissions also take into account air pollutant controls used to lower the emissions.

You can also use a potential to actual multiplier to estimate potential emissions. The potential to actual multiplier is based on a ratio of potential hours of operation to actual hours of operation: 8,760 hours per year (24 hours per day multiplied by 365 days per year) divided by the actual hours per year. For example, if you operate 2,500 hours per year, your potential to actual multiplier would be 8,760 hours per year divided by 2,500 hours per year or 3.5.

22.7.1.4 Example Potential-To-Emit, Permit-Limited Potential-To-Emit, And Actual Emissions Calculations

The following is a simplified example of the various emission types. Acme, Inc. has one air emission unit, a widget maker, that gives off 25 pounds of volatile organic compound emissions every hour it operates. If it operated for a year (e.g., 24 hours per day and 365 days per year or 8,760 hours per year), it would emit:

(25 pounds/hour)*(8,760 hours/year)/(2,000 pounds/ton)=109.5 tons/year

This potential-to-emit is over the major source threshold of 100 tons per year. Even the Acme, Inc. only operates the widget maker around 2,000 hours per year, because the potential-to-emit is above the major source threshold, they would be classified as a major source. A major source has more regulatory requirements and higher annual fees, so the facility requests a permit limit that would limit the widget maker hours of operation to 7,000 hours per year. Below are the various emission types, associated hours of operation and emissions.

Acme Inc. Air Emission Types and Emissions

| Emission Type | Annual Hours of Operation | Volatile Organic Compound Emissions |

|---|---|---|

| Potential-To-Emit | 8,760 | 109.5 tons per year |

| Permit-Limited Potential-To-Emit | 7,000 | 87.5 tons per year |

| Actual | 2,000 | 25 tons per year |

22.7.2 Pollutants

Air quality regulations apply to facilities that emit criteria pollutants (carbon monoxide, lead, nitrogen dioxide, particulate matter, sulfur dioxide, volatile organic compounds) and hazardous air pollutants.

22.7.3 Air Emission Types

Air emissions are typically divided into two types: point source and fugitive. Fugitive emissions are defined by the Clean Air Act as:

“. . . those emissions which could not reasonably pass through a stack, chimney, vent, or other functionally-equivalent opening.”[2]

Point source emissions are air emissions that cannot be defined as fugitive emissions.

According to a 1987 Environmental Protection Agency (EPA) Memorandum:

“The preamble to the 1980 NSR regulations characterizes nonfugitive emissions as ‘. . . those emissions which would ordinarily be collected and discharged through stacks or other functionally equivalent openings.’ … This does not mean that the applicant’s decision on whether to collect emissions is the deciding factor; in fact, the reviewing authority makes the decision on which emissions would ordinarily be collected and which therefore are not considered fugitive emissions.”[3]

22.7.4 Emission Estimation Background

To estimate the regulated air emissions from a facility’s operations, you have four options: emission factors, mass balance calculations, emission monitoring and control device manufacturer data as described in the following sections.

22.7.4.1 Emission Factors

An emission factor is a value or formula that relates the quantity of a pollutant released to the atmosphere with an activity associated with the release of that pollutant[4]. Emission factors are normally expressed as the weight of a pollutant divided by a weight, volume, or duration of the activity emitting the pollutant. Emission factors are normally the average values of available data and are generally assumed to be representative of long-term averages for activity[5].

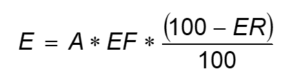

The general equation for emission estimation using an emission factor is:

where:

E = emissions from the source,

A = activity rate of the source,

EF = emission factor for the source, and

ER = overall percentage emission reduction efficiency.

If a facility does not use a device or practice to physically limit or reduce the emissions, then the emissions reduction efficiency is equal to zero. If a control device, such as a dust collector, is used to reduce the emissions, then the overall emissions reduction efficiency is calculated based on the capture efficiency of the control device (i.e., how much of the emissions are collected and sent to the control device), and the control device destruction or removal efficiency.

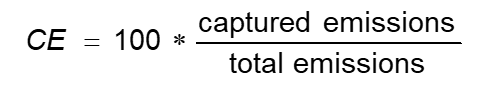

The capture efficiency, which in my experience is often overlooked, is the percentage of emissions that are captured and exhausted to a control device and is determined based on the following equation:

where:

CE = percentage of emissions captured and exhausted to control device.

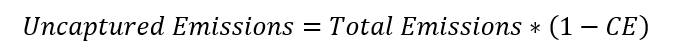

The uncaptured emissions (i.e., not sent to a control device) can be calculated as:

where:

CE = percentage of emissions captured and exhausted to control device, and

Note: The values for CE need to be percentages (i.e., less than 1: for example 95% should be 0.95).

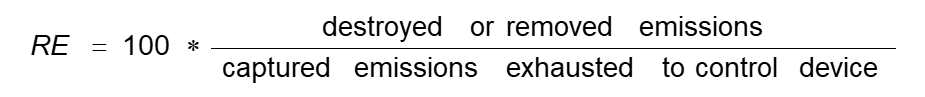

The removal or control efficiency is the percentage of emissions exhausted to the control device that are destroyed or removed by the control device and is determined based on the following equation:

Where:

RE = percentage of emissions removed or destroyed by the control device.

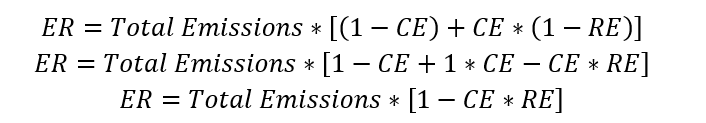

The overall emissions reduction efficiency is the product of the capture efficiency of the control system and control device destruction or removal efficiency and is determined based on the following equation:

where:

ER = overall emissions reduction efficiency,

CE = percentage of emissions captured and exhausted to control device, and

RE = percentage of emissions removed or destroyed by the control device.

Note: The values for CE and RE need to be percentages (i.e., less than 1: for example 95% should be 0.95).

AP-42 states that: “When estimating emissions for a long-time period (e.g., one year), both the device removal efficiency and the capture efficiency terms account for upset periods as well as routine operations.”[6]

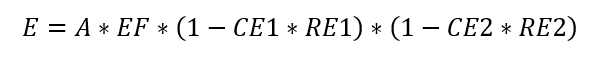

Multiple control devices can make the calculations more complicated. If the emissions control devices operate independently (e.g., operate in parallel), the emissions calculation may be written as:

where:

E = emissions from the source,

A = activity rate of the source,

EF = emission factor for the source,

CE1 = percentage of emissions captured and exhausted to first control device,

RE1 = percentage of emissions removed or destroyed by the first control device,

CE2 = percentage of emissions captured and exhausted to second control device, and

RE2 = percentage of emissions removed or destroyed by the second control device.

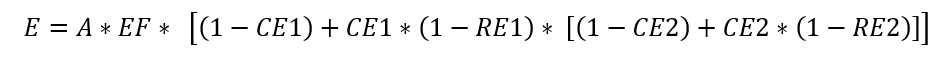

If the emissions control devices operate dependently (i.e., the emissions coming off of one control device are routed to the next control device), the emissions calculation may be written as:

where:

E = emissions from the source,

A = activity rate of the source,

EF = emission factor for the source,

CE1 = percentage of emissions captured and exhausted to first control device,

RE1 = percentage of emissions removed or destroyed by the first control device,

CE2 = percentage of emissions captured and exhausted to second control device, and

RE2 = percentage of emissions removed or destroyed by the second control device

22.7.5.1.1 Source Classification Codes

The Environmental Protection Agency (EPA) has categorized different pollutant emitting activities into source classification codes (SCCs)[7]. The source classification codes (SCCs) are used as primary identifiers for the Environmental Protection Agency’s (EPA) air programs and emission factors[8].

The Environmental Protection Agency (EPA) has developed emission factors for some of the source classification codes (SCCs). The availability of an emission factor for a source classification codes (SCCs) or a pollutant does not imply that the Environmental Protection Agency (EPA) believes the source does not emit that pollutant or that the source should not be included as an air emitting source.

22.7.5.1.2 AP-42

The Environmental Protection Agency first published “AP-42: Compilation of Air Emissions Factors” in 1972[9]. AP-42 is a compilation of air pollutant emission factors developed and compiled from source test data, material balance studies, and engineering estimates[10]. AP-42 is divided up by industry type with a chapter for each as shown below.

- Chapter 1 External Combustion Sources

- Chapter 2 Solid Waste Disposal

- Chapter 3 Stationary Internal Combustion Sources

- Chapter 4 Evaporation Loss Sources

- Chapter 5 Petroleum Industry

- Chapter 6 Organic Chemical Process Industry

- Chapter 7 Liquid Storage Tanks

- Chapter 8 Inorganic Chemical Industry

- Chapter 9 Food and Agricultural Industries

- Chapter 10 Wood Products Industry

- Chapter 11 Mineral Products Industry

- Chapter 12 Metallurgical Industry

- Chapter 13 Miscellaneous Sources

- Chapter 14 Greenhouse Gas Biogenic Sources

- Chapter 15 Ordnance Detonation[11]

The appendices also contain valuable information. Appendix A contains Miscellaneous Data and Conversion Factors that are used for the emissions calculations. Although you may be able to find this data from other sources on-line, it is common practice in the air permitting realm to use the data in this appendix.

Because the published emission factors are subject to change, you may want to include the emission factor information, where available, in the appendices to the air permit application document and provide some background information on the emission factor.

22.7.5.1.3 WebFIRE

The Factor Information Retrieval (FIRE) Data System is a database of the Environmental Protection Agency’s (EPA) recommended emission estimation factors for criteria and hazardous air pollutants[12]. WebFIRE is the on-line database of the Environmental Protection Agency’s (EPA) emission factors that allows you to search for emission factors based on source classification code (SCC), pollutant and control device[13]. The emission factor values in AP-42 are also included in WebFIRE, but AP-42 contains background information on the emission activity that is not included in WebFIRE.

22.7.5.1.4 Tanks 4.09d Software Program

For volatile organic compounds stored in tanks, you may use the Environmental Protection Agency’s (EPA) TANKS 4.09d Software program (TANKS) to estimate emissions. According to the Environmental Protection Agency (EPA) Website:

“TANKS is a Windows-based computer software program that estimates volatile organic compound (VOC) and hazardous air pollutant (HAP) emissions from fixed- and floating-roof storage tanks. TANKS is based on the emission estimation procedures from Chapter 7 of Environmental Protection Agency’s (EPA) Compilation of Air Pollutant Emission Factors (AP-42).[14]”

AP-42 has equations for these calculations, but it requires a number of calculations to estimate emissions. Tanks 4.09d may not work on computers with modern Windows operating systems[15].

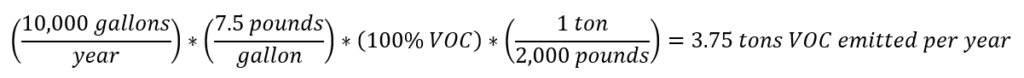

22.7.5.2 Mass Balance Calculations

The mass balance calculation typically assumes that the quantity of material used is emitted. This is often used for VOCs in paints and solvents. For example, to calculate the VOC emissions, you need to calculate the quantity of VOC used. In the example below, a site used 10,000 gallons of a solvent and the safety data sheet for the solvent says that it has a density of 7.5 pounds per gallon and a VOC concentration of 100%.

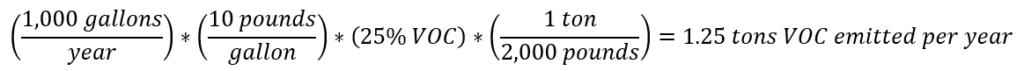

In the next example, a site used 1,000 gallons of a paint and the safety data sheet for the paint says that it has a density of 10 pounds per gallon and a VOC concentration of 25%.

22.7.5.3 Emissions Monitoring

Some air construction permits require one-time or periodic tests of your emissions which are typically referred to as stack tests. If this is a quantitative test, versus a qualitative test such as an opacity observation, the results may be used for your emissions calculations. Some sites may be required to install emissions monitoring systems on equipment such as a continuous emissions monitoring system (CEMS). This will provide direct measurement of the emissions.

22.7.5.4 Control Device Manufacturer’s Data

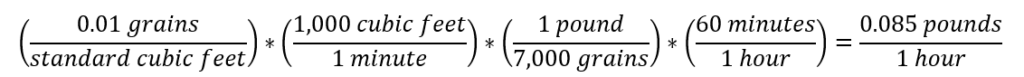

Some control devices are designed to limit emissions to a particular threshold. For example, a dust collector might limit emissions to 0.01 grains per standard cubic foot. Grains are a unit of weight often used for dust collectors and 7,000 grains equals a pound. If you know the blower flowrate in standard cubic feet per minute, you can multiply the dust collector emission limit by the blower flowrate to get an emissions estimate. In the example below, the dust collector blower has a flowrate of 1,000 cubic feet per minute and the dust collector has a guaranteed emission limit of 0.01 grains per standard cubic foot:

22.7.6 References

[1] “Potential to Emit (PTE) Guidance for Specific Source Categories” Memorandum by John S. Seitz, Director Office of Air Quality Planning and Standards and Eric Schaeffer, Director Office of Regulatory Enforcement, OECA dated April 14, 1998 (https://www.epa.gov/sites/default/files/2015-08/documents/lowmarch.pdf#:~:text=The%20Environmental%20Protection%20Agency%20%28EPA%29%2C%20in%20its%20current,emit%20under%20its%20physical%20and%20operational%20design.%20)

[2] 40 Code of Federal Regulations 70.2, May 1, 2007

[3] October 6 1987 Memorandum from Gerald A. Emison, Director Office of Air Quality Planning and Standards (MD-10) to David P. Howekamp, Director Air Management Division, Region IX regarding Emissions from Landfills

[4] “AP-42 Compilation of Air Emission Factors” Environmental Protection Agency, Volume 1: Stationary Point and Area Sources, Introduction, page 1 (https://www.epa.gov/sites/default/files/2020-09/documents/c00s00.pdf)

[5] “AP-42 Compilation of Air Emission Factors” Environmental Protection Agency, Volume 1: Stationary Point and Area Sources, Introduction, page 1 (https://www.epa.gov/sites/default/files/2020-09/documents/c00s00.pdf)

[6] “AP-42 Compilation of Air Emission Factors” Environmental Protection Agency, Volume 1: Stationary Point and Area Sources, Introduction, page 1 (https://www.epa.gov/sites/default/files/2020-09/documents/c00s00.pdf)

[7] “Introduction to Source Classification Codes and their Use for EIS Submissions” Environmental Protection Agency (https://sor-scc-api.epa.gov/sccwebservices/sccsearch/docs/SCC-IntroToSCCs.pdf#:~:text=The%20U.S.%20EPA%20uses%20Source%20Classification%20Codes%20%28SCCs%29,and%20some%20of%20the%20emissions%20they%20generate%20include%3A) accessed January 1, 2023, page 1.

[8] Ibid, page 1.

[9] “AP-42: Compilation of Air Emissions Factors” Environmental Protection Agency website (https://www.epa.gov/air-emissions-factors-and-quantification/ap-42-compilation-air-emissions-factors) accessed January 2, 2023.

[10] Ibid

[11] Ibid

[12] “Factor Information Retrieval System (FIRE) – Frequent Questions” Environmental Protection Agency Technology Transfer Network Clearinghouse for Inventories & Emissions Factors website (https://www3.epa.gov/ttnchie1/faq/firefaq.html#:~:text=The%20Factor%20Information%20Retrieval%20%28FIRE%29%20Data%20System%20is,the%20chemicals%20emitted%2C%20and%20the%20emission%20factors%20themselves.) accessed January 2, 2023.

[13] “Welcome to Webfire” Environmental Protection Agency website (https://cfpub.epa.gov/webfire/) accessed January 2, 2023.

[14] “TANKS Emissions Estimation Software, Version 4.09D” Environmental Protection Agency website (https://www.epa.gov/air-emissions-factors-and-quantification/tanks-emissions-estimation-software-version-409d) accessed January 2, 2023.

[15] Ibid

I am always open to comments and suggestions. You can contact me using the form below.